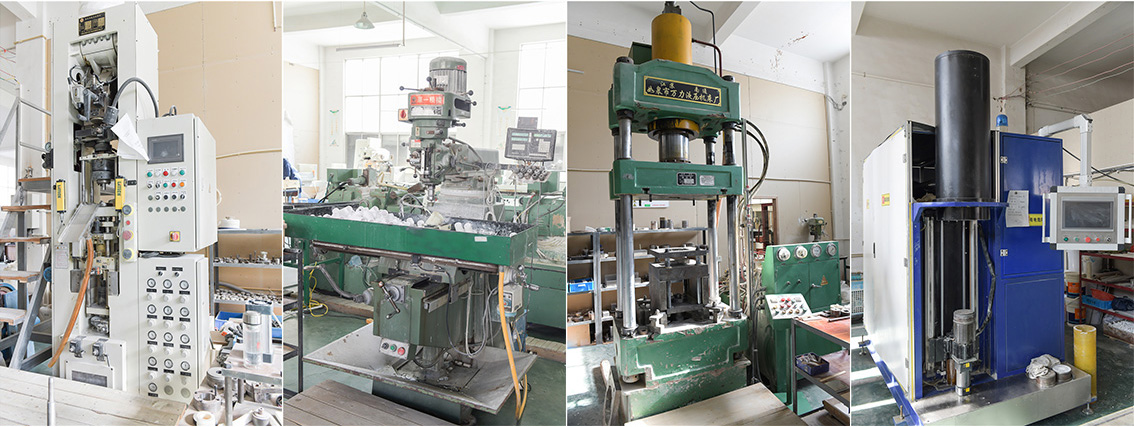

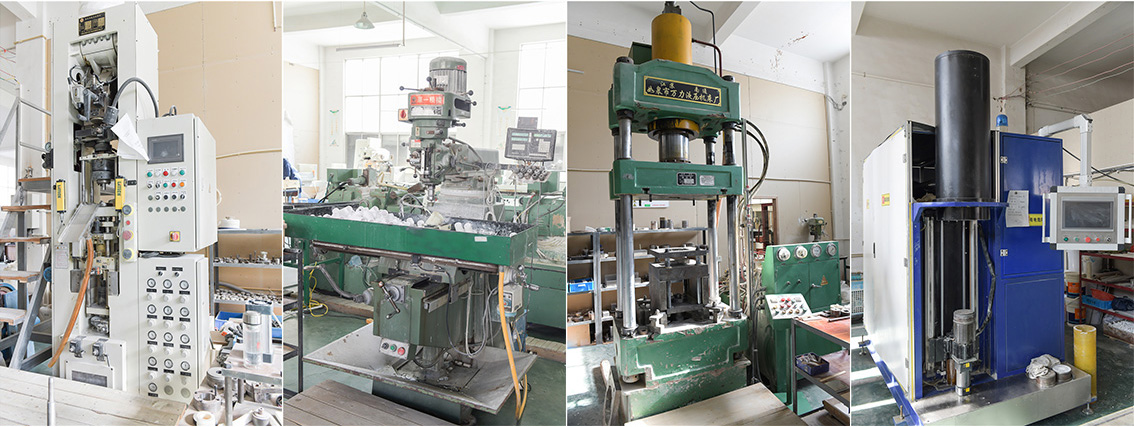

XDL Ceramics has extensive in-house machining facilities - including CNC machines,axis machining centers, drilling, milling, grinding, polishing, sawing, tapping, threading and turning - to enable us to manufacture technical ceramic components to the highest specifications.

CNC Machining Centers

XDL Ceramic has extensive experience with high-tolerance technical ceramic milling, grinding and polishing of unfired and fired ceramics. Our state-of-the-art equipment allows us to offer a variety of technical ceramic services including:

CNC Ceramic Milling & Grinding

Lapping & Polishing

Brazing & Joining

Metalizing

Glazing

With multiple vertical machine centers and turning centers, we are able to keep all operations in house.

Through the use of CAD/CAM computer software, we are able to optimize the cutting paths to get the most efficient programs that will keep cost low and provide the highest quality possible.

Machining Tolerances

Grinding General tolerances of ±.02mm, can achieve ±.01mm with a surface finish of N2/N3

Turning general tolerance of ±.03mm, can achieve ±.01mm with a surface finish of N4/N5

Milling general tolerance of ±.03, can achieve ±.01 with a surface finish of N4/N5.

CNC Milling bed capacity of 1000mm in X and 510mm in Y.

CNC Milling spindle speed of 12,000 rpm

CNC Milling and turning machines are all equipped with synchronized rigid tapping for perfect internal threads

CNC Turning capabilities of 250mm diameter with power tooling

All tolerances can be improved upon depending on the size, shape & geometry of the technical ceramic part. XDL Ceramic is dedicated to ensuring we make only the highest quality parts that meet or exceed our customers specifications. In order to ensure that all of our products are achieving this goal we utilize an Axion high-performance CNC CMM and have full tractability on all of our parts.